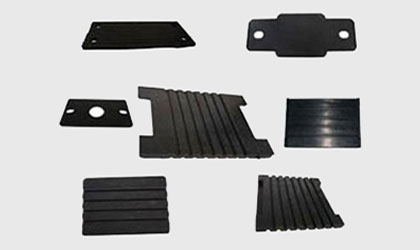

Rail Pad

The rail pad, originally called sole plate, is used when rail is attached to concrete, rather than timber, ties or sleepers. Rail pads function to reduce fatigue cracking of the concrete ties, believed to be driven by impact and vibration from the passing train. It is thought that the rail pads act in two ways: they diminish shock or impact loads by providing compliance, and they reduce (by isolation and perhaps by damping) resonant vibrations excited in the concrete ties and accommodate vibration deflections in the rail sections between the ties. AGICO have differernt types of tie plates for sale.

The raid pad prevents rail-sleeper abrasion and the crushing of the sleeper under the rail foot. Rubber rail pads are normally designed to a specified load-deflection characteristic. The initial stiffness of the rail pad is designed to be low so that that their deformations under the springs toe loads is quite substantial. This ensures that the rail pad remains in intimate contact with the rail despite any vertical movements of the latter. When the wheel is over the pad, the latter’s stiffness must be high to prevent large movements which can result in the metal spring becoming loose. Such a load-deflection characteristic can be obtained by introducing grooves in the rubber rail pads. Rubber pad or grooved rubber rail pad are made up of rubber or plastic to dampen the shocks of vibrations of a passing train.

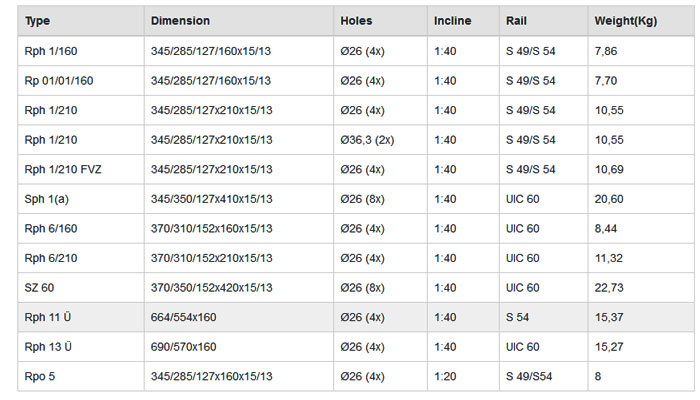

Technical Parameter of Rail Tie Plates: We Have Differernt Types of Tie Plates for Sale

We also produce all types of tie plates according to customer’s drawings.If you need the railroad tie plates, please contact us.

Get In Touch

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel FREE to contact us!